Custom-Made Orthoses with 3D Printing for Orthopedic Pediatric Application

DOI:

https://doi.org/10.30441/smart-elab.v15i.144Keywords:

Patient-specific medical device, Reverse engineering, 3D printing, Pediatric OrthopedicsAbstract

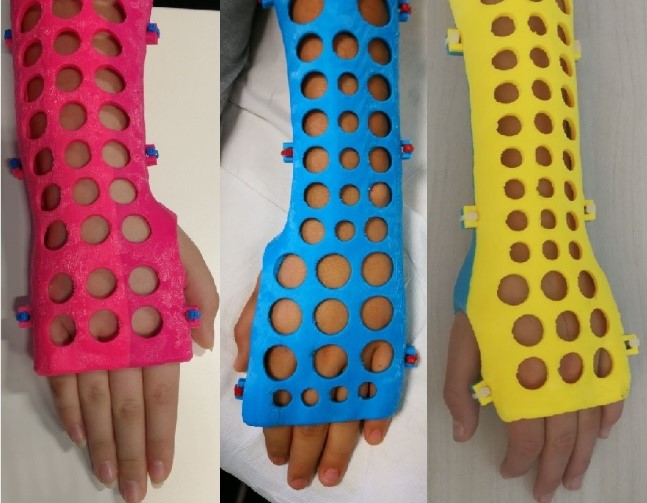

Distal forearm fractures represent about 70Using classic plaster cast can cause discomfort and skin damage as well as infections and irritations that can aggravate during the immo- bilization treatment. Nowadays, there are several works about 3D printed cast, focused on different aspect of process, but few have undertaken a clinical trial. The aim of this paper is to show a reverse engineering and 3D printing-based process to produce patient specific casts, ventilated and waterproof. Production process described in this work has been used in the clinical trial activity performed at Paediatric Orthopaedic Department of Santobono Hospi- tal in Naples according to the project approved by ethical committee to test this new kind of immobilizer on 30 patients.

The process follows the technical consideration issued by FDA about 3D printed medical devices and it consists of three phases forearm scan, processing and printing.

ISSN: 2282-2259 by Progetto Calliope

ISSN: 2282-2259 by Progetto Calliope